Two popular off-the-shelf systems are available from Ronstan and Karver, and their units are very similar in design and components. The ProDrive and other cables are considerably light and pliable, so they’re easy to manage on the boat. However, for boats up to around 50 feet, we make them in-house at West Marine Newport, using a product from Marlow called ProDrive, which is made from a Vectran parallel core, and a Kevlar wrapped polyester cover. These are made by several manufacturers to order, such as Composite Rigging and Future Fibres. Each sail, however, requires its own anti-torsion cable.

Code zero furler code#

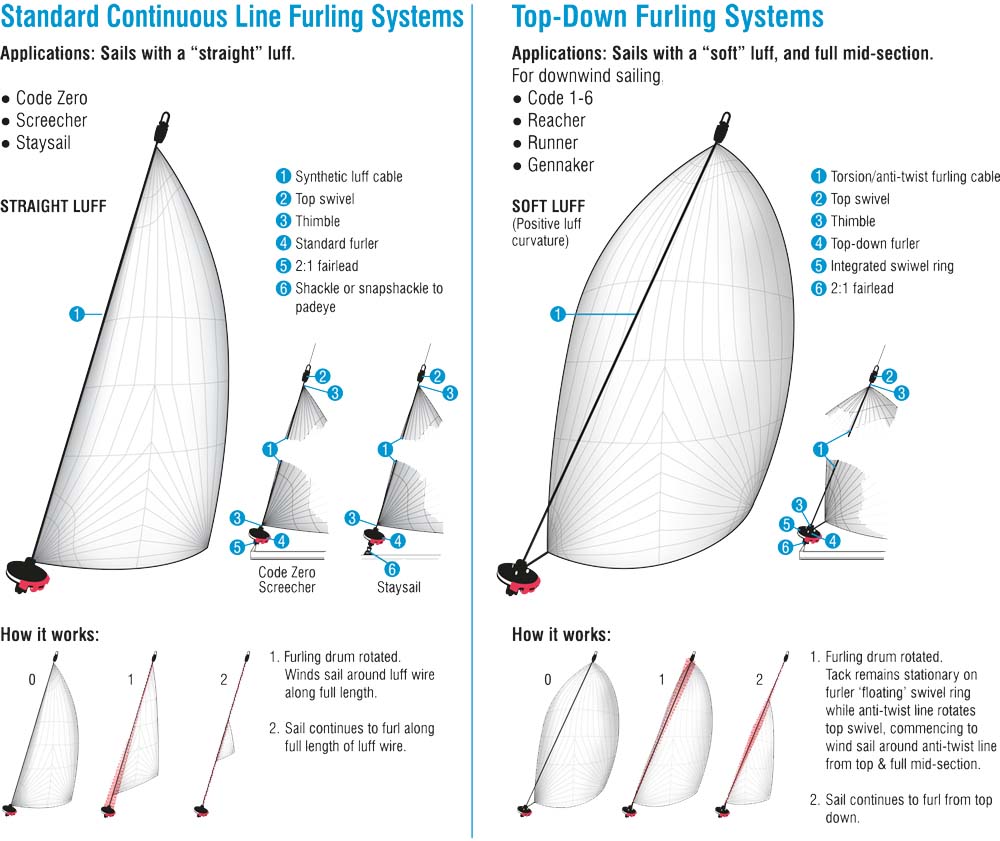

Only one furler assembly is required-drum and top swivel-regardless of how many asymmetric spinnakers or code zeros are in the sail inventory. Retrofitting existing furling assemblies to a top-down setup only requires a few items. The head of the sail is attached, usually lashed, to a thimble integrated into the top of the cable. As opposed to a traditional headsail furling system, a top-down furling system keeps the sail separate from the cable, and twists-or furls-around it. It is engineered not to twist as the sail is furled, therefore allowing the entire assembly to turn in unison. The anti-torsion cable is a fiber cable that runs from the top swivel to the furling drum. This anti-torsion cable is the critical piece of the system, and the one that has undergone the most significant development. The tack, foot, and bottom portion of the sail remain unfurled as the head and top start a tight furl around an anti-torsion cable. The engineering that makes this possible is a free-floating swivel on top of the furling drum to which the sail is tacked. The bottom portion of the sail is rolled last. It furls the asymmetric spinnaker, or gennaker, from the head down. The potential advantages for a racing team, either around the buoys or offshore, include simplifying sail changes and eliminating the need to continuously band or pack spinnakers.Ī top-down furler operates just as its name implies.

These systems allow you to roll asymmetric spinnakers as simply as you would a jib on a roller furler. Today, at the top of the grand-prix scene, there has been an important advancement on the furling front: top-down furlers. More recently, string-drop systems have come into favor, where a drop line attached somewhere in the middle of the sail is run to either a drum, winch, or purchase system to pull the sail into the forward hatch.

In the higher realm of grand-prix racing, to maximize sail shape and usage, the standard has been to simply douse the spinnaker with all-hands forward, and therefore not use a sock.

This has also been the case in the shorthanded and buoy-racing scene: Either socks or wools are required to keep all that sailcloth under control as spinnakers go up and down. For many years, the standard technique for handling cruising spinnakers has been the ubiquitous and often awkward “sock,” which is a way to deploy and strike a spinnaker in a controlled manner, especially when sailing shorthanded.

0 kommentar(er)

0 kommentar(er)